Can a 24V power supply be used to supply a 12V device?

1. Introduction

In electronic equipment and power systems, a mismatch between the power supply and the voltage requirements of the equipment is a common problem. Especially in a power supply environment, technicians may encounter a situation where they only have a 24V power supply at hand, but need to power 12V devices. At this time, many amateurs or technicians may ask: "Is it possible to directly use a 24V power supply to power 12V devices?" The answer is clear: it is not recommended to directly use a 24V power supply to power 12V devices. This can result in equipment damage, data loss, and even a potential fire hazard. The specific reasons will be explained in detail below. At the same time, this article will also provide some practical alternative solutions for your reference. I hope it can help you in need.

2. Why don’t we recommend directly using 24v power supply to supply 12v equipment?

Technical background

In terms of voltage requirements and device compatibility, most electronic devices are designed with specific voltage requirements and tolerance ranges. For example, 12V devices typically operate between 10-15V. When the power supply voltage exceeds this range, the device cannot operate stably, and internal components may even be damaged due to too high or too low voltage. Therefore, when trying to connect power supplies and equipment with different voltages, you must first confirm the voltage requirements and tolerance range of the equipment.

Manufacturers usually clearly indicate the applicable input voltage range in the specification sheet or equipment nameplate, and sometimes indicate the maximum tolerance allowed by the equipment. It is incompatible to directly use 24V power supply to supply 12V equipment. Voltage beyond the design range of the equipment will bring unpredictable consequences.

Key reasons

From the perspective of the impact and risk of voltage mismatch, the main risk of directly using 24V power supply to supply 12V equipment is overvoltage. The internal circuitry of electronic devices is very sensitive to supply voltage, and voltages outside the design range can cause serious problems, such as the following:

Circuit overheating: The high voltage of the 24V power supply will cause the circuit to overheat, and the internal components will heat up rapidly, causing thermal runaway or damage. Electronic components such as resistors, capacitors, diodes, etc. may generate abnormal heat or even melt or burn out when the voltage tolerance range is exceeded.

Permanent failure: High voltage may quickly burn out capacitors, resistors, semiconductor devices and other components, causing permanent damage to the equipment. For example, excessive voltage can cause transistor breakdown or MOSFET failure, and may even cause the inductor coil in the power module to burn out.

Fuse failure: Fuses designed for 12V systems may not be able to withstand the high voltage of 24V and will blow quickly and lose their protective effect. Moreover, the overvoltage protection circuitry in some devices may not respond in time to high voltage conditions, causing further damage to the internal circuitry.

Fire hazard: Overvoltage may cause a short circuit on the circuit board or overheating of the internal circuit, posing a potential fire hazard. Especially when the electrolytic capacitors or wires on the circuit board are overloaded, sparks may occur and even ignite other components or lines.

Shortened lifespan: Even if the equipment can work at high voltage for a short time, being in a state exceeding the design voltage for a long time will accelerate aging and shorten the lifespan. For example, when an electrolytic capacitor is subjected to a voltage higher than the designed value for a long time, electrolyte leakage or internal resistance increases, eventually leading to circuit failure.

In addition, when using various types of power products, it is important to understand the importance of manufacturer recommendations. Equipment manufacturers usually provide clear power supply voltage requirements to ensure that equipment operates in a stable and safe environment. Using a power supply outside of the voltage range in direct violation of the manufacturer's recommendations may not only cause the device to fail, but may also void the warranty. Therefore, always follow the power supply voltage requirements provided by the manufacturer to avoid equipment damage or warranty loss due to voltage mismatch.

3. Solutions and alternatives

If you currently only have a 24V power supply but need to power a 12V device, perhaps consider the following alternatives to resolve the voltage mismatch problem:

Buck converter

A DC-DC buck converter is an electronic device that can reduce a higher voltage to a target voltage. Use a buck converter to steadily step down the 24V voltage to 12V. However, there are a few things to keep in mind when choosing the right converter:

Power Capacity: Make sure the converter's power rating meets the equipment's needs. Too small a power capacity may cause the converter to be overloaded and unable to function properly.

Example: If the maximum power consumption of a 12V device is 120W, the converter should be rated at least 150W to ensure stable power supply.

Voltage range: Make sure the input voltage range matches the 24V power supply, and the output voltage can be stable at 12V.

Example: Select a buck converter with an input voltage range of 18-30V and a stable output voltage of 12V.

Brand and Quality: Choose reliable brands and quality products to ensure the stability and long life of the converter.

Suggestion: You can choose well-known brands on the market such as Meanwell, Victron Energy, etc. to avoid voltage instability problems caused by inferior products.

Heat dissipation and protection: Choose a converter with good heat dissipation function and overcurrent and overvoltage protection functions to ensure long-term stable operation of the equipment.

Example: DC-DC converter with aluminum alloy casing and fan cooling, and has input overvoltage, output overcurrent, and short circuit protection functions.

Alternative power supply

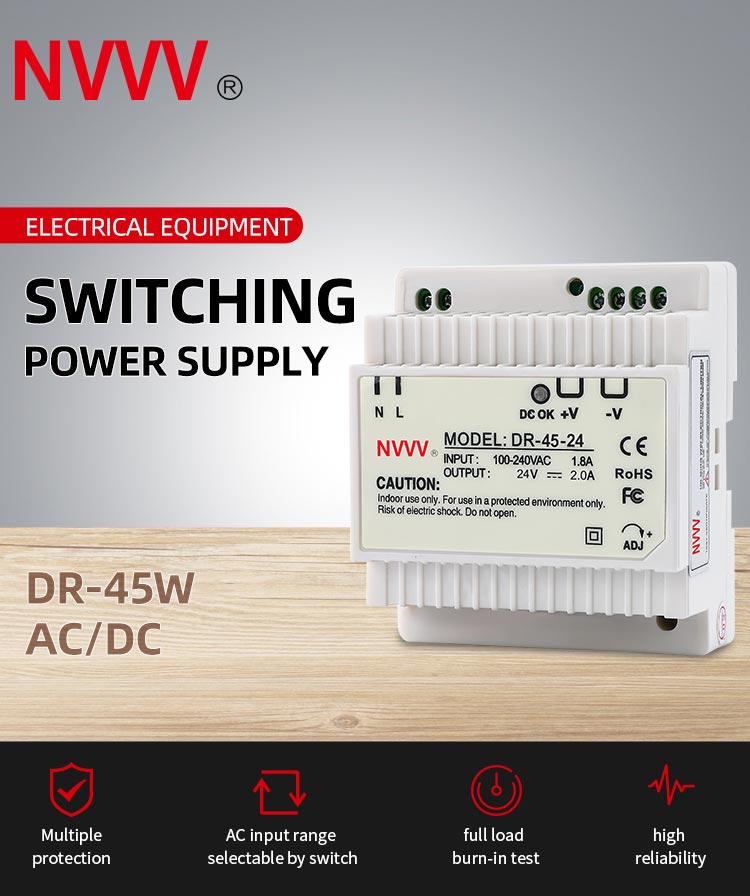

Directly using a dedicated power supply that meets the requirements of 12V equipment is the safest and most reliable solution. When purchasing a suitable 12V power supply, you should pay attention to the following points:

Voltage range: Make sure the output voltage of the power supply is within the allowable range of the device. Generally speaking, the output voltage error of a regulated power supply should be controlled within ±5%.

Example: A regulated power supply with an output voltage of 12V ± 0.6V is suitable for powering 12V devices.

Power capacity: The rated power of the power supply should be higher than the maximum power consumption of the device to ensure stable power supply.

Example: If the maximum power consumption of the device is 120W, the power supply should be rated at least 150W.

Stability: Choose a power supply with stable output to avoid voltage fluctuations from affecting the equipment.

Recommendation: Choose a regulated power supply with active PFC function to ensure the stability of the output voltage.

Protection function: The power supply should have overcurrent and overvoltage protection functions to ensure the safety of power supply.

Example: 12V regulated power supply with overvoltage, overcurrent, and short circuit protection.

Dual voltage power supply

Some power supplies can switch between 24V and 12V output, such as dual voltage switching mode power supplies. If such a power supply is available, it can be set to 12V output to meet the needs of the device. However, before operation, you should carefully read the power supply specifications and operation manual to ensure correct connection and settings.

Example: Some switching power supplies on the market support multi-voltage output modes and can be adjusted to 12V mode through switches.

Independent power supply design

If there are both 24V and 12V devices in the system, consider providing independent power supplies for devices with different voltage levels. This can not only ensure the stable operation of the equipment, but also avoid the risk of damage caused by voltage mismatch.

Solution example: Use a 24V power supply to power 24V devices, while using a buck converter to reduce 24V to 12V to power 12V devices.

4.Additional tips

Testing and Validation

Before connecting the power supply to the device, use a multimeter to test the power supply output voltage to ensure that the buck converter or power supply can provide a stable 12V. Things to note when testing:

Voltage accuracy: The voltage should be stable at 12V or within the allowable range of the device.

Current Capacity: Make sure the power supply can provide sufficient current capacity to meet the needs of the device.

Continuous testing: Conduct long-term stability testing to ensure the reliability of the power supply system.

Overcurrent protectionConsider adding a fuse or circuit breaker to the circuit to provide extra protection in the event of overcurrent or short circuits. A fuse should be selected that matches the power consumption of the device to ensure that it blows quickly when the current is overloaded and protects the circuit from damage.

Selection Guide

The rated current of the fuse should be slightly higher than the maximum current demand of the equipment. For example, if the maximum current demand of the equipment is 10A, a fuse with a rated current of 12A should be selected.

Voltage monitoring

Use a voltage monitor to monitor power supply voltage changes in real time to prevent equipment damage caused by voltage fluctuations. The following are recommendations for the selection and use of voltage monitors:

Monitoring range: Make sure the voltage range of the monitor covers the output range of the 12V power supply.

Example: Select a voltage monitor with a monitoring range of 10-15V.

Alarm function: Choose a monitor with overvoltage and undervoltage alarm functions to promptly remind you of voltage abnormalities.

Recommendation: A voltage monitor with a buzzer alarm function can immediately alert the user when the voltage is abnormal.

Data recording: If you need to monitor voltage changes for a long time, you can choose a monitor with data recording function to keep track of the power supply status at any time.

5.Conclusion

In short, directly using a 24V power supply to supply 12V equipment is extremely risky, and can easily lead to equipment damage, data loss, fire and other safety hazards. Therefore, it is not recommended to directly use 24V power supply to supply 12V equipment. It is recommended to use safer alternatives such as step-down converters, dedicated 12V power supplies, etc. to ensure stable operation of the device and avoid the risk of damage. In addition, when powering 12V equipment, you should always follow the manufacturer's voltage requirements, select an appropriate power supply or buck converter, and add corresponding protection and monitoring measures to ensure safe and stable operation of the equipment.