Choosing an SMPS? Ask These 5 Questions First

Table of Contents

What Is an SMPS and How Does It Work?

Where Is SMPS Used and Why Is It Preferred?

How to Determine the Right SMPS Specifications for Your System?

What Factors Affect the Long-Term Reliability of an SMPS?

What Makes One SMPS Brand More Trustworthy Than Another?

In today's fast-paced industrial and commercial environments, Switched Mode Power Supplies (SMPS) have become essential for ensuring efficient and stable power conversion. Whether you're powering automation equipment, communication devices, or control systems, selecting the right SMPS can make a significant difference in performance, energy efficiency, and product lifespan. This guide addresses five important questions to help you understand SMPS technology and make better purchasing decisions.

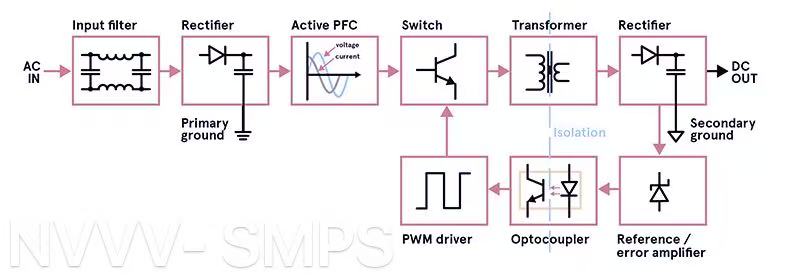

What Is an SMPS and How Does It Work?

Definition and Basic Principle

An SMPS, or Switching Mode Power Supply, is an electronic power supply that incorporates a switching regulator to convert electrical power efficiently. Unlike linear regulators, SMPS rapidly switch on and off to regulate output voltage, using energy storage components like inductors or capacitors.

Types of SMPS

AC-DC Converters: Convert alternating current to direct current, suitable for most industrial equipment.

DC-DC Converters: Step up or step down voltages for embedded systems or telecommunications.

Isolated vs. Non-Isolated: Depending on safety and interference requirements.

Efficiency and Heat Management

One of the major advantages of SMPS is high efficiency, often reaching 85–95%, resulting in less heat generation and reduced energy loss compared to traditional power supplies.

Where Is SMPS Used and Why Is It Preferred?

Industrial Applications

Switching power supply is widely used in:

Factory automation systems

Process control panels

PLC and HMI units

Security and surveillance systems

Key Advantages for End Users

Compact Size: Smaller footprint enables easy installation in control cabinets.

Energy Efficiency: Critical for reducing operational costs.

Voltage Stability: Keeps equipment running smoothly even under voltage fluctuations.

Longer Equipment Life: Reduced heat stress means longer lifespan for connected devices.

How to Determine the Right SMPS Specifications for Your System?

Voltage and Current Rating

Start by calculating the total power consumption of all devices to be powered. Always add a 20–30% safety margin. For instance, if your equipment needs 80W, opt for at least a 100W unit.

Input Type and Range

Wide Input Range (85-264VAC): Suitable for global applications or environments with fluctuating voltage.

Single-Phase vs. Three-Phase Input: Depending on load size and local power grid.

Output Features to Consider

Ripple and Noise: Choose low-ripple models to avoid interference in sensitive electronics.

Protection Mechanisms: Look for short circuit, overload, overvoltage, and over-temperature protections.

SMPS Specification Checklist

|

Parameter |

Recommended Range / Option |

Why It Matters |

|

Output Power |

120% of actual load requirement |

Allows safety margin and future expansion |

|

Output Voltage |

5V / 12V / 24V / 48V (depending on device) |

Must match the voltage rating of your connected equipment |

|

Input Voltage Range |

Wide Range (85–264VAC) |

Supports global voltage variations and unstable power grids |

|

Mounting Type |

DIN-rail or Panel Mount |

Should match control cabinet layout |

|

Ripple & Noise |

≤1% of output voltage |

Important for sensitive electronics and stable operation |

|

Protection Features |

OVP, OCP, SCP, OTP |

Prevents failure due to overloads, short circuits, overheating |

|

Cooling Mechanism |

Natural (fanless) or forced air (fan) |

Affects durability, noise, and maintenance |

|

Efficiency |

≥85% |

Reduces power loss and operational costs |

What Factors Affect the Long-Term Reliability of an SMPS?

Environmental Conditions

Temperature Range: Ensure compatibility with the actual operating environment.

Humidity and Dust Protection: Enclosures with IP ratings help resist moisture and particles.

Mounting Type: DIN-rail or panel-mount must match your enclosure design.

Component Quality

Capacitors and MOSFETs: High-grade components offer greater durability.

Cooling Methods: Passive (fanless) cooling reduces noise and mechanical wear.

Maintenance and Monitoring

Select SMPS units that support diagnostics or LED indicators to simplify system checks and preventive maintenance.

What Makes One SMPS Brand More Trustworthy Than Another?

Certification and Compliance

Brands with proper certifications ensure safer, globally accepted products. Look for units that comply with CE, RoHS, or UL standards depending on your regional requirement.

Warranty and Support

A reliable manufacturer will offer multi-year warranties and strong after-sales support, minimizing downtime in case of failure.

Real-World Feedback

Positive case studies and consistent performance across various industries provide assurance of product quality.

Conclusion

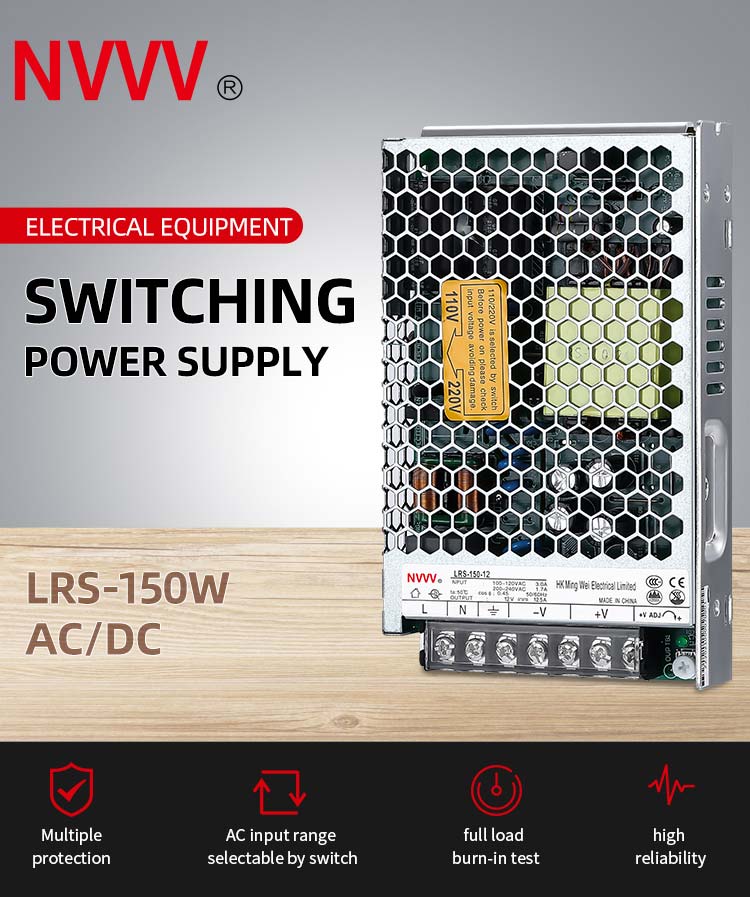

Selecting the right Switch Mode Power Supply (SMPS) involves more than just checking wattage or voltage. You need to assess the working environment, power quality, load requirements, and safety features to ensure long-term reliability and efficiency. Among various suppliers in the market, NVVV offers a range of industrial-grade SMPS products known for their durability, smart protection features, and compatibility with both DIN-rail and panel-mounted applications.