LED Driver Switching Mode Power Supply: What Should You Know Before Choosing One?

In today's fast-evolving lighting industry, LED technology has become the standard for both indoor and outdoor applications. But behind every efficient LED system lies a core component that often goes unnoticed — the LED driver switching mode power supply. This compact yet powerful device ensures that LEDs receive the right voltage and current, protecting them from power fluctuations and maximizing their lifespan. Whether you're designing lighting for a commercial facility, a smart building, or a large-scale outdoor project, choosing the right SMPS is critical to the success and reliability of your installation. This article explores the key questions you should ask when selecting an LED driver SMPS — covering everything from technical specifications to design features and real-world applications.

Table of Contents

-

Why Is a Switching Mode Power Supply Crucial for LED Drivers?

-

How Do You Determine the Right Output Specifications for Your Application?

Why Is a Switching Mode Power Supply Crucial for LED Drivers?

Ensuring Energy Efficiency and Performance

Switching Mode Power Supplies (SMPS) are essential for LED driver systems due to their superior power conversion efficiency, often reaching up to 85–95%, depending on the load and circuit design. This efficiency not only reduces electricity bills but also lowers thermal stress on components, thereby extending the life span of both the power supply unit and the LED fixtures themselves. In applications like retail lighting, factories, or urban lighting infrastructure, where hundreds or thousands of LEDs operate continuously, these savings add up significantly. Moreover, the compact size of SMPS allows for better integration into space-constrained environments, such as LED panels or recessed ceiling lights, without compromising ventilation.

Protecting Your LEDs from Voltage Instability

LEDs operate within a narrow voltage and current tolerance. A fluctuation outside of this range can damage the internal circuitry or degrade luminous efficacy over time. SMPS units are designed with active regulation circuits that maintain stable DC output even under unstable AC input or varying load conditions. Many advanced models include power factor correction (PFC) to further stabilize the current draw, especially in high-wattage systems. Features like surge protection, soft start, and EMI filters not only protect the LEDs but also improve system-wide compatibility, particularly in networked lighting where multiple drivers are interconnected. This reliability is especially critical in public spaces, tunnels, or hospital environments, where any flicker or failure can affect safety or operations.

How Do You Determine the Right Output Specifications for Your Application?

Matching Voltage and Current Ratings

One of the most important steps in selecting the right LED driver switch mode power supply is to match the output voltage and current to your LED configuration. LEDs are highly sensitive to overcurrent, which can lead to immediate damage or progressive lumen degradation. If you're using a series connection, the driver must deliver the total forward voltage of all LEDs combined; for parallel configurations, the driver must be capable of supplying adequate current to each branch. For example, a 24V constant voltage SMPS is suitable for LED strips in commercial signage, while high-bay lighting may require constant current drivers with outputs like 350mA, 700mA, or 1050mA, depending on the chip specification. Choosing an underpowered driver results in dimming and inefficiency, while an overpowered one can cause excessive heat or shortened LED lifespan.

Considering Load Type and Operating Conditions

Different lighting setups have different electrical behaviors, known as load types. Static indoor installations may have a resistive load, but dimmable or dynamic lighting systems introduce capacitive or inductive characteristics, which can stress the power supply. Therefore, it's important to consider if your system involves PWM dimming, analog dimming, or digital control protocols such as DALI or DMX. Additionally, the environmental conditions are crucial. For outdoor applications like street lights or landscape lighting, ensure the power supply has an IP65 or higher rating, with adequate protection against humidity, dust, and UV exposure. Temperature tolerance also matters: some units operate reliably from -30°C to +70°C, making them suitable for both desert regions and cold European winters. This ensures long-term durability even in harsh or fluctuating climates.

What Design Features Improve Reliability and Longevity?

Thermal Management and Enclosure Quality

Heat is the silent killer of electronic components, especially in LED driver SMPS systems that operate for extended periods. A high-quality switching power supply must incorporate effective thermal design features to ensure consistent performance. This can include passive cooling via finned aluminum housings, thermal pads, or integrated heat sinks that dissipate internal heat efficiently. For higher wattage models—such as 100W or above—active cooling solutions, like silent fans or hybrid airflow systems, may also be integrated. The enclosure material plays a role as well: industrial-grade metal housings provide better shielding and heat resistance compared to plastic ones. These mechanical characteristics are especially relevant when installing the power supply in enclosed or poorly ventilated spaces such as LED panels, wall cavities, or waterproof casings.

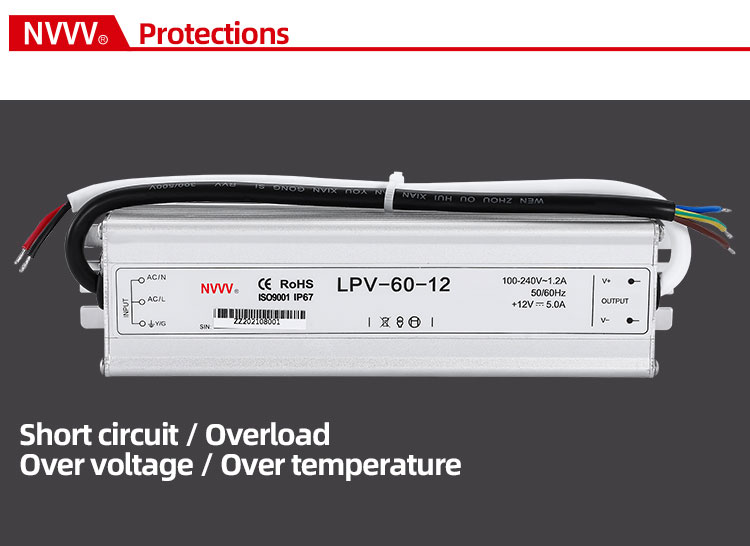

Certifications and Regulatory Compliance

To ensure safety, quality, and compliance with international markets, LED driver switching mode power supplies should carry relevant certifications, such as CE, RoHS or UL, depending on the target region. These not only affirm that the product meets electrical safety and electromagnetic compatibility (EMC) requirements but also ensure compliance with environmental regulations, which is becoming increasingly important in Europe and the Middle East. For example, RoHS compliance guarantees the absence of hazardous substances, while CE marking indicates adherence to EU directives. Some power supplies also meet Class II insulation standards, which further eliminate the need for grounding in certain applications. These certifications are particularly crucial in commercial lighting projects, government infrastructure, and hospital or educational environments, where procurement departments require documentation before installation.

What Are the Key Application Scenarios for LED Driver SMPS?

Indoor and Outdoor Lighting

LED driver switching mode power supplies are widely used across a range of indoor and outdoor applications due to their adaptability and efficiency. In indoor settings such as shopping malls, office buildings, and museums, SMPS units are paired with LED strips, downlights, and panel lights to ensure bright, flicker-free illumination. Their compact size allows easy installation behind walls or inside ceilings. For architectural or accent lighting, dimmable SMPS units enable seamless brightness adjustment to enhance ambiance while saving energy. Outdoors, the requirements are more stringent — IP67-rated or waterproof metal-case drivers are essential for applications like parking lot lights, stadium floodlights, or public square lighting. These units withstand rain, dust, and temperature extremes, ensuring continuous operation even during storms or seasonal changes.

Smart Control and Automation Integration

With the rise of smart buildings and intelligent lighting systems, modern SMPS units are evolving to support digital dimming protocols such as DALI, 0–10V, or PWM control. This enables centralized control over brightness, schedules, and energy consumption, which is ideal for energy-conscious facilities, hotels, or airports. The switching mode power supply must offer low ripple current to ensure smooth dimming and avoid flickering, particularly in camera-monitored environments like retail displays or conference halls. Additionally, SMPS units with built-in surge protection and EMI filters ensure that automation networks remain stable and interference-free, even in complex multi-zone lighting setups. These capabilities make SMPS not just a power source, but a critical enabler of advanced lighting control strategies, helping facilities transition toward IoT-ready infrastructure.

Conclusion: Choosing a Trusted Brand Matters

When it comes to selecting a LED Driver Switching Power Supply, making the right decision is more than just comparing specs. It's about ensuring long-term system stability, energy efficiency, and compliance with international standards — especially for large-scale lighting installations in commercial or industrial environments. The ideal SMPS should provide not only the correct voltage and current but also robust environmental protection, smart dimming support, and safety certifications that satisfy procurement requirements and end-user expectations.

As a professional supplier of industrial power solutions, NVVV offers a comprehensive range of LED driver SMPS units designed for high performance and durability. Whether your application involves interior commercial lighting, harsh outdoor conditions, or smart automation networks, NVVV's certified, efficient, and customizable products can provide the reliability and flexibility your project demands.