Switching Mode Power Supply: 5 Key Questions Before You Choose

When it comes to powering modern industrial systems, a reliable and efficient switching mode power supply (SMPS) is essential. Whether you're building automation systems, lighting infrastructure, or telecommunications equipment, choosing the right SMPS can directly impact performance, safety, and cost-efficiency. But with so many options available, how can you make an informed decision? This article answers five key questions that will help you understand SMPS technology, evaluate your application needs, and select the best solution for your operation.

Table of Contents

What Is a Switching Mode Power Supply and How Does It Work?

How Do You Determine the Right SMPS for Your Application?

Where Are Switching Mode Power Supplies Commonly Used?

How Can You Ensure Long-Term Reliability of Your SMPS?

What Makes One SMPS Brand Stand Out from the Others?

What Is a Switching Mode Power Supply and How Does It Work?

Understanding the Basics

A switching power supply (SMPS) is an advanced type of power supply that uses high-frequency switching and control circuits to efficiently convert electrical power from one form to another—typically from AC to DC or DC to another DC voltage. Unlike linear power supplies, which dissipate excess voltage as heat, SMPS minimizes energy loss by rapidly switching power transistors on and off, thus regulating the output voltage with high efficiency. This makes SMPS the preferred choice for modern electronics and industrial automation applications, where compact size and energy efficiency are critical.

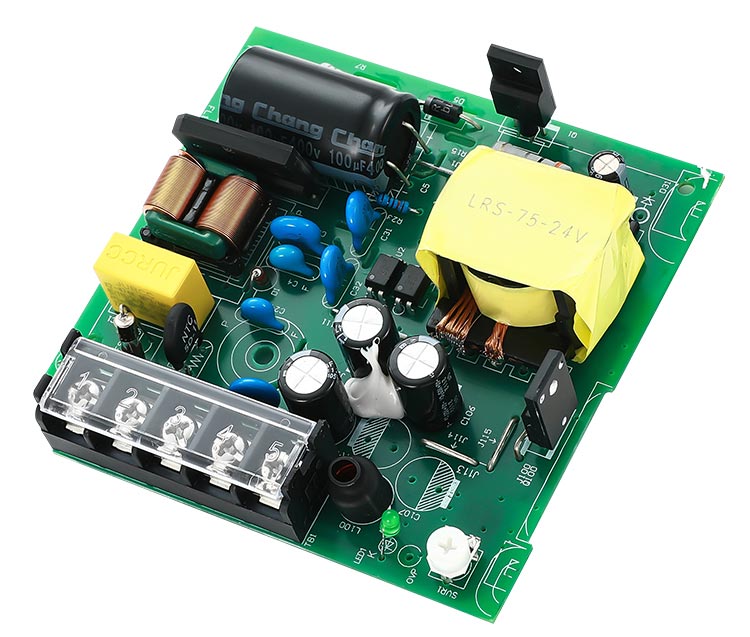

Main Components and Operation

The operation of an SMPS starts with the input rectifier, which converts AC power into DC. This DC is then fed into a high-frequency oscillator and a switching transistor, which converts it into a pulsed high-frequency AC signal. A transformer then steps this voltage up or down as needed, followed by rectification and filtering to produce a smooth and regulated DC output. The feedback loop constantly monitors the output voltage and adjusts the switching duty cycle to maintain voltage stability, even with varying loads or input fluctuations. These control mechanisms allow for precise voltage regulation and faster response times than traditional power supplies.

Why Efficiency Matters

Efficiency is often a deciding factor when choosing a power supply for industrial or commercial applications. With efficiencies reaching 85–95%, SMPS units drastically reduce electricity consumption compared to older technologies. This not only cuts energy costs but also minimizes heat output, reducing the need for additional cooling systems. In high-density electrical cabinets or temperature-sensitive environments—common in European automation plants or Middle Eastern telecom enclosures—this becomes a crucial advantage. Additionally, many modern SMPS models include power factor correction (PFC) to reduce harmonic distortion, which further improves overall system efficiency and compliance with power quality standards.

How Do You Determine the Right SMPS for Your Application?

Power Requirements

The first step in selecting a suitable switching mode power supply is calculating your system’s actual power demands. This involves determining both the voltage and current requirements of all devices the SMPS will power. To ensure system reliability, it’s best to include a 20–30% margin above the total calculated load to accommodate unexpected power surges or future expansions. For example, if your system needs 5A at 24V, choosing a 24V 6.5A SMPS will provide enough buffer while avoiding overload conditions. Selecting the right wattage rating helps avoid premature failure and ensures continuous operation, even under variable loads.

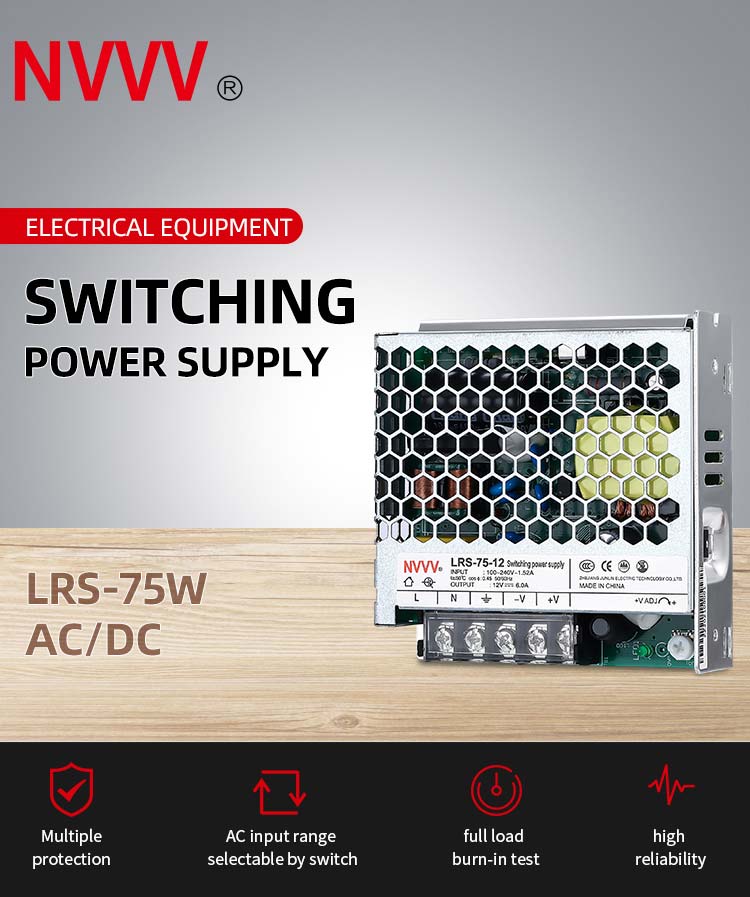

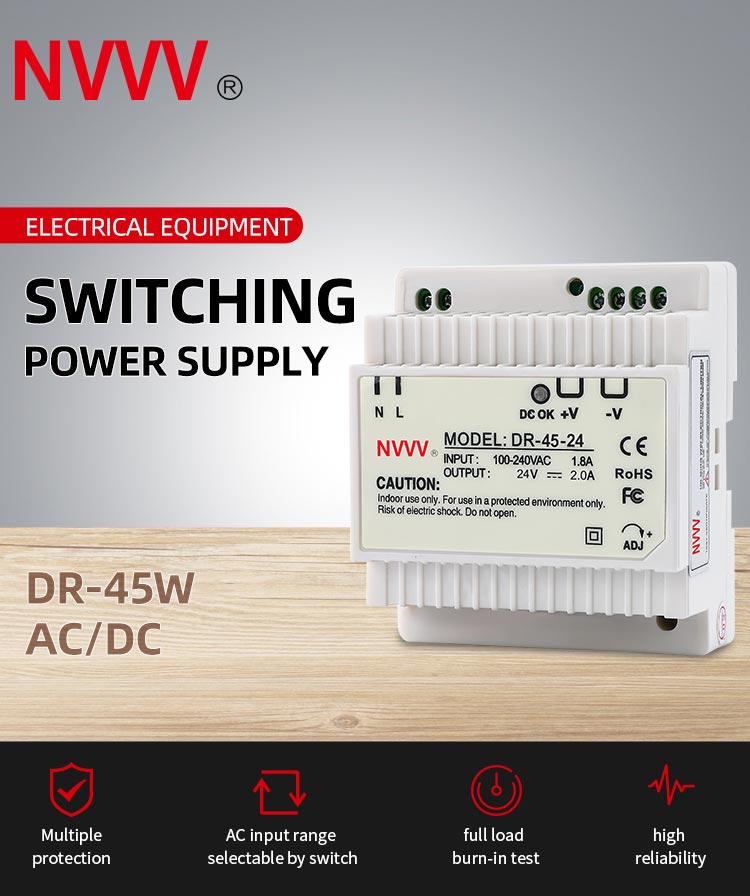

Form Factor and Mounting Type

Beyond power ratings, physical design is another crucial factor. Switching mode power supplies come in several form factors such as enclosed types for harsh environments, open-frame models for integration into larger systems, and DIN-rail mounted types ideal for modular control panels. In Europe, DIN-rail SMPS models are widely used in industrial automation due to standardized panel sizes. Meanwhile, enclosed SMPS units with fan cooling or passive heat sinks are preferred in Middle Eastern installations where ambient temperatures can be high. Always ensure your selected model fits the physical constraints of your application environment.

Protection Features to Consider

To guarantee long-term durability and system safety, modern SMPS models offer integrated protection features. These typically include short-circuit protection (SCP), over-voltage protection (OVP), over-current protection (OCP), and thermal shutdown mechanisms. These safeguards help prevent equipment damage due to unexpected faults or environmental stress. In mission-critical systems like PLCs or HMI interfaces, built-in protections are not optional—they're essential. Additionally, look for input surge protection if the device will be deployed in regions with unstable grid supply. Choosing an SMPS with wide input voltage tolerance (e.g., 85–264VAC) also enhances versatility and global compatibility.

Where Are Switching Mode Power Supplies Commonly Used?

Industrial Automation Systems

In automated production environments, switching mode power supplies are the backbone of reliable control. They power programmable logic controllers (PLCs), sensor networks, relays, and servo drives, ensuring continuous data flow and command execution. In European manufacturing plants—where precision and energy efficiency are vital—SMPS helps reduce downtime and optimize equipment lifecycle. In the Middle East, where factory environments often deal with fluctuating temperatures, industrial-grade SMPS with built-in thermal protection and wide voltage range are frequently used in oil refineries, food processing, and smart packaging lines.

LED Lighting and Building Management Systems

SMPS is central to the growing field of smart infrastructure. In both commercial and residential buildings, low-voltage SMPS (like 12V or 24V models) power LED strips, lighting controllers, security cameras, and HVAC interfaces. In cities like Dubai, where high-rise smart buildings are the norm, switching mode power supplies are integrated with building automation systems to provide stable and efficient power for thousands of interconnected devices. European BMS integrators also prefer SMPS for its compact form factor and high reliability—especially in energy-certified green buildings.

Telecom and Communication Equipment

Telecom base stations, Wi-Fi routers, access points, and fiber optic converters all depend on the stable, filtered DC output from SMPS. With increasing digital infrastructure demand across Europe and 5G network expansion in the Middle East, SMPS units are deployed in remote outdoor cabinets and rooftop enclosures. Their high efficiency helps reduce battery backup sizes and minimizes heat load in confined spaces. Models with conformal coating and extended temperature ratings are especially suited for telecom installations exposed to dust, moisture, or wide temperature variations.

How Can You Ensure Long-Term Reliability of Your SMPS?

Thermal Management

Proper heat dissipation is essential for extending the lifespan of any switch mode power supply. High operating temperatures can accelerate the degradation of internal components, particularly capacitors and switching transistors. To address this, many high-end SMPS models include aluminum heat sinks, intelligent fan control, or support for natural convection. In compact enclosures or control cabinets with limited airflow—common in factory settings—installing the SMPS in a vertical position or near ventilation paths can significantly enhance thermal efficiency. It’s also advisable to leave spacing around the unit to avoid heat buildup.

Quality of Components and Certifications

Reliable performance starts with the components inside. SMPS units using high-temperature-rated electrolytic capacitors, low-RDS(on) MOSFETs, and high-frequency transformers generally offer better performance under load. Reputable manufacturers conduct strict endurance testing and often comply with multiple regional certifications such as CE (Europe), UKCA (UK), and RoHS (environmental safety). Buyers in Europe often prioritize such compliance as part of procurement requirements, while in the Middle East, extended durability under heat and power fluctuations is a key deciding factor. Always verify that the SMPS is tested for 100% full-load operation before shipment.

Environmental Suitability

Installing SMPS in harsh or unstable environments demands a higher protection level. For dusty, humid, or outdoor conditions, select IP65 or IP67-rated models with sealed housings and corrosion-resistant materials. In offshore installations or coastal areas—especially relevant in Middle Eastern maritime projects—salt spray resistance is also crucial. If the application involves frequent vibrations (e.g., in transportation or elevator systems), go for units tested for shock and vibration. Some industrial-grade SMPS options are designed to withstand 5–500Hz vibration and comply with IEC standards for mechanical durability.

What Makes One SMPS Brand Stand Out from the Others?

Customization and After-Sales Support

One of the most critical differentiators between SMPS brands lies in their ability to tailor solutions to specific customer needs. While many offer standard voltage and current outputs, top-tier manufacturers go a step further—providing customized voltage ranges, dual or triple output channels, or built-in communication interfaces like RS-485 or CANbus for system integration. For example, in automation-heavy industries or smart grid applications, the ability to embed remote monitoring into the power supply adds operational value. Moreover, dedicated technical support—especially in local languages or time zones—is often what sets a trusted partner apart from a one-time vendor.

Stock Availability and Global Delivery

In industrial projects, time is often more valuable than cost. Delays due to unavailable stock or long lead times can cause setbacks across the supply chain. Reliable SMPS brands maintain global warehouses or authorized local distributors that ensure consistent inventory. For instance, quick delivery across Europe from centrally located hubs or fast regional shipping within the Gulf Cooperation Council (GCC) region can reduce downtime and support scheduled maintenance cycles. Brands that offer ready-to-ship options for popular models—like 24V 5A, 12V 10A, or 48V 2.5A—are often preferred by integrators working under tight deadlines.

Cost-to-Performance Ratio

While price is a factor, it should never override performance. The true cost of an SMPS includes energy efficiency, durability, maintenance, and potential downtime from failures. A cheaper unit that fails after one year is costlier in the long run than a premium one that runs for five years under full load. Evaluating factors like MTBF (mean time between failures), thermal tolerance, and component origin can help clarify value. Brands like NVVV offer a solid combination of affordability and high industrial reliability, making them a compelling choice for long-term system stability and cost-effectiveness.

Conclusion

Switched mode power supplies are no longer just accessories—they are vital components in every modern electrical system. From improving energy efficiency to enhancing system stability and integration, the right SMPS brings both immediate and long-term benefits. By understanding what to look for—technical specifications, environmental resilience, protection features, and support—you can confidently choose a power supply that supports your business goals. For reliable, industry-proven SMPS solutions, NVVV offers a full range of models tailored to diverse applications in automation, building systems, and telecommunications.