Switching Mode Power Supply Guide for Industrial Efficiency: Top 5 Insights

In today's rapidly evolving industrial landscape, maintaining reliable and efficient power delivery is essential. Whether you're managing a factory floor, a control system, or a data-driven production line, Switching Mode Power Supplies (SMPS) play a central role in delivering stable, regulated power. But how do you choose the right one for industrial needs? This article answers five key questions industrial buyers often ask when sourcing switching mode power supplies for demanding applications.

Table of Contents

What Is a Switching Mode Power Supply and Why Is It Used in Industrial Environments?

How Does a Switching Mode Power Supply Improve Industrial Efficiency?

What Are the Key Parameters to Consider When Selecting an SMPS?

Where Are Switching Mode Power Supplies Commonly Used in Industrial Settings?

What Are the Benefits of Choosing a High-Quality SMPS Manufacturer?

Conclusion: Choosing the Right SMPS Partner

What Is a Switching Mode Power Supply and Why Is It Used in Industrial Environments?

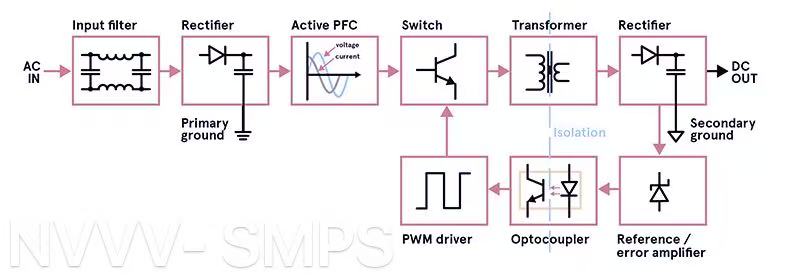

Efficient Conversion and Compact Design

A switching mode power supply (SMPS) converts AC or DC input voltage into a stable, regulated output using high-frequency switching transistors and transformers. Unlike linear power supplies, which rely on large transformers and dissipate more energy as heat, SMPS operates at higher efficiency levels—often above 85%—with much smaller form factors. This efficiency is achieved by rapidly switching the input on and off and using energy storage components like inductors and capacitors to deliver power smoothly.

Industrial Relevance

In industrial settings, power stability and compact design are crucial. Machines often operate under variable loads and in electrically noisy environments. SMPS technology ensures voltage consistency even when the input supply fluctuates, thanks to its closed-loop regulation and filtering capabilities. For example, in an assembly line that includes programmable logic controllers (PLCs), proximity sensors, and touchscreen HMIs, an SMPS ensures all components receive the clean, stable voltage they require to function without error.

Use Case Snapshot

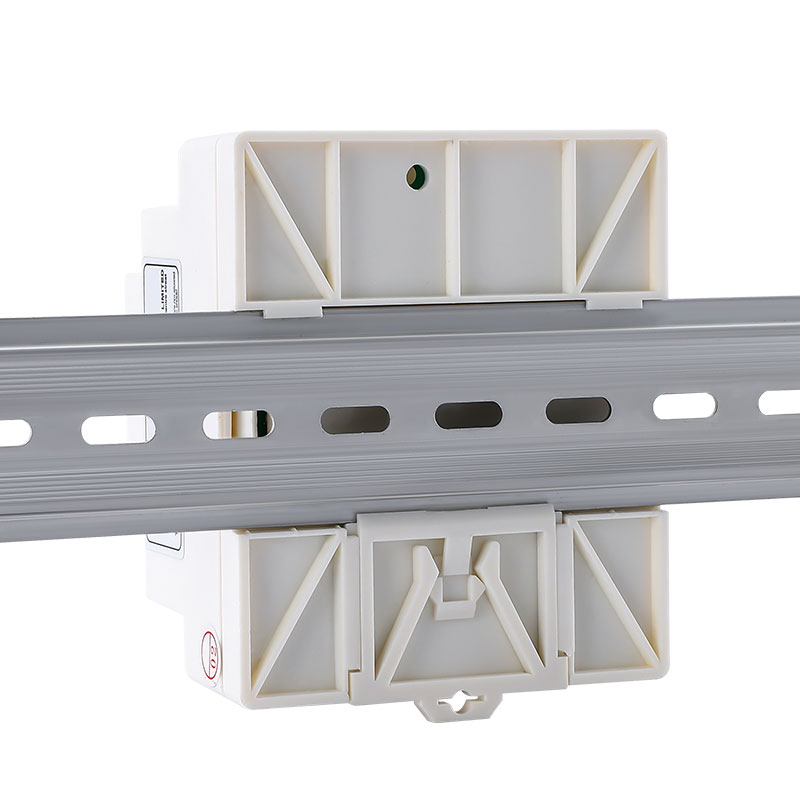

Consider a modern CNC machine or robotic assembly system. These units require 24V DC for control logic, safety interlocks, and relay switching. An SMPS can easily convert the factory's 230V AC supply into reliable 24V DC without bulky transformers or excess heat. Moreover, when placed inside electrical cabinets, space is always a concern. The slim profile of DIN-rail-mounted SMPS units allows easy installation alongside breakers, contactors, and terminals—making it the preferred power solution for industrial engineers and system integrators.

How Does a Switching Mode Power Supply Improve Industrial Efficiency?

Energy Saving & Load Regulation

One of the primary reasons industrial users prefer SMPS is its superior energy efficiency. Traditional linear power supplies often lose significant energy as heat, especially under full load. In contrast, switching power supplies can achieve efficiency ratings between 85% to 95%, depending on the load profile and design quality. This leads to substantial reductions in energy bills, especially in facilities running 24/7. Over time, this efficiency directly translates to lower operational costs and better ROI on equipment investments.

Stable Power Delivery in Harsh Conditions

Industrial environments are notorious for power instability, voltage spikes, harmonic distortion, and electromagnetic interference (EMI). A high-quality SMPS includes advanced filtering, EMI shielding, and internal feedback circuits to maintain stable voltage output, even in the face of such disturbances. This is particularly valuable when powering sensitive control systems or communication modules that must not fail under fluctuating grid conditions.

Reduced Cooling Requirements

Thanks to its high efficiency, SMPS generates less heat, which minimizes the need for active cooling systems like fans or external ventilation. In high-density electrical enclosures, this thermal advantage leads to lower enclosure temperatures, extending the life of surrounding devices and reducing the risk of thermal shutdowns or fire hazards. Fanless SMPS designs are also favored in clean environments like food processing or pharmaceutical plants, where dust accumulation must be minimized.

Long-Term Reliability

A switching mode power supply isn't just efficient—it's built for endurance. Models designed for industrial use often incorporate protections against overvoltage, overload, short circuits, and over-temperature shutdowns. These features shield both the power supply and connected devices from damage, improving system reliability and reducing downtime. Some advanced units also offer MTBF (mean time between failures) ratings above 500,000 hours, a crucial metric for engineers focused on predictive maintenance.

Application Highlight

In an automated bottling plant, where conveyor motors, photoelectric sensors, and control logic work in unison, even a minor voltage drop can halt production. Using SMPS with regulated output and load balancing capacity prevents such incidents, ensuring uninterrupted operations and reduced maintenance calls.

What Are the Key Parameters to Consider When Selecting an SMPS?

Voltage, Current, and Power Rating

The first and most essential criteria are the input and output specifications. Industrial SMPS models are commonly designed to accept wide input ranges, such as 85–264V AC or 100–370V DC, to adapt to different grid conditions globally. The output voltage (e.g., 12V, 24V, 48V DC) must match the requirements of the load—like sensors, PLCs, solenoids, or motor drivers. Equally important is the output current capacity. For example, a 24V 10A SMPS delivers up to 240W. Always account for a 30% safety margin to prevent overload in dynamic load scenarios.

Form Factor and Mounting Type

Industrial environments require flexible installation options. DIN-rail mounted SMPS are standard in control cabinets, offering easy integration and better wire management. However, for harsh environments or standalone applications, metal-enclosed models with IP-rated casings offer better protection. Pay attention to enclosure size, terminal accessibility, and airflow clearance when choosing a unit for compact spaces.

Thermal Performance and Cooling

Operating temperature range is critical for installations in high-heat environments like steel plants or outdoor electrical enclosures. Choose models rated for at least -20°C to +70°C. Fanless convection cooling is preferred for low-maintenance installations, while high-power units may include temperature-controlled fans to optimize longevity.

Built-in Protections

Look for industrial-grade features like:

Short-circuit protection to automatically shut off output during faults.

Over-voltage and over-current protection to safeguard the load.

Over-temperature protection to avoid thermal runaway or shutdowns.

These ensure that even under adverse conditions, the system remains stable and safe.

Certifications and Standards Compliance

Depending on the industry and export region, compliance with CE , RoHS, UL, or EN/IEC standards may be mandatory. This is especially important for systems integrated into international machinery or exported across borders. Certified products often undergo stricter testing and quality assurance, reducing risk and improving documentation for audits or factory acceptance tests (FATs).

Additional Considerations

Advanced SMPS units may include features like:

Remote sensing terminals to compensate for voltage drops on long cables.

Adjustable output voltage knobs for fine-tuning during installation.

LED indicators or relay alarms to monitor status visually or programmatically.

Real-World Tip

For example, in an industrial automation panel requiring dual-voltage supply, choosing an SMPS with dual outputs (e.g., 24V and 5V) can reduce component count and wiring complexity—leading to lower installation time and fewer points of failure.

Where Are Switching Mode Power Supplies Commonly Used in Industrial Settings?

Automation and Control Panels

In modern automation systems, switch mode power supplies are at the core of control cabinets, powering everything from programmable logic controllers (PLCs) to I/O modules, signal converters, and relay coils. These components demand precise and reliable DC voltages, especially 24V, to function effectively. Without a stable power source, sensors may malfunction, data transmission may be interrupted, and machine cycles may be delayed. SMPS not only provides the needed voltage stability but also helps simplify wiring and reduce heat buildup inside panels.

Manufacturing & Processing Plants

Manufacturing lines in industries such as automotive, pharmaceuticals, plastics, packaging, and textiles often include multiple motorized components, robotic units, and feedback control systems. Each of these subsystems requires isolated power delivery to minimize interference and ensure safety. SMPS units are often deployed in these systems to power motor controllers, touchscreen HMIs, barcode scanners, and machine vision cameras. Their compact design allows for multi-unit installation in limited cabinet space, and their low EMI footprint makes them ideal for electronically sensitive environments.

Energy and Infrastructure Systems

Industrial-grade SMPS are also widely used in energy management systems, including solar inverters, wind turbine controllers, battery storage units, and grid-connected smart meters. These applications benefit from SMPS units' wide input range and ability to function reliably even with fluctuating voltage sources. In infrastructure applications—such as airport control rooms, railway signal cabinets, or tunnel monitoring systems—the power supply must be fail-safe and rugged. SMPS with redundant configuration or parallel operation support is especially useful in these mission-critical areas.

Smart Building and Factory Lighting Systems

Switching power supplies also support LED drivers in smart industrial lighting systems. In large facilities with hundreds of luminaires, centralizing power control via SMPS allows automated dimming, zone-based control, and integration with IoT platforms for energy monitoring. Their ability to work with modbus or CAN interfaces makes them highly compatible with industrial IoT ecosystems.

Table: Typical Industrial Applications of SMPS

|

Application Area |

SMPS Role |

|

PLC Control Cabinets |

Delivering regulated DC to logic circuits |

|

Conveyor Systems |

Powering motor controllers and safety interlocks |

|

HVAC & Environmental Controls |

Running actuators, sensors, and VAV modules |

|

Smart Factory Lighting |

Supplying power to intelligent LED fixtures |

|

Renewable Energy Control Units |

Providing stable DC for inverters and monitoring systems |

|

Utility & Power Grids |

Supporting telemetry, SCADA nodes, and fault detection units |

Example from the Field

In a food packaging facility operating under strict hygiene standards, SMPS is used to power washdown-rated sensors and stainless steel enclosures. A fanless, sealed SMPS with IP65 rating not only delivers reliable power but also withstands daily high-pressure cleaning—making it indispensable in such wet and corrosive environments.

What Are the Benefits of Choosing a High-Quality SMPS Manufacturer?

Minimized Downtime and Risk

In industrial operations, every minute of unplanned downtime leads to productivity loss, missed deadlines, and additional labor costs. Low-cost or poorly engineered SMPS units often fail under stress—whether due to voltage spikes, thermal overload, or aging components. In contrast, a high-quality manufacturer uses premium-grade capacitors, transformers, and PCBs, and implements rigorous quality control, ensuring each unit performs reliably even in the harshest conditions. Investing in proven power supplies significantly reduces the frequency of field replacements and emergency maintenance.

Consistent Product Lifecycle Support

Reliable manufacturers maintain long-term product consistency and support across multiple generations of a product family. For OEMs or system integrators, this means easier inventory management and smoother design-in processes when scaling up production. Many top-tier suppliers offer documentation continuity, ensuring the same electrical characteristics, mounting dimensions, and certifications over time—a critical factor in regulated industries like food processing, medical device manufacturing, or transportation.

Tailored Industrial Features and Innovation

Leading SMPS brands don't just offer off-the-shelf solutions—they provide custom options such as:

Remote monitoring and control terminals (for diagnostics and voltage adjustments)

Built-in redundancy or hot-swap capabilities (for critical systems like data centers or oil rigs)

Conformal coating for use in corrosive or high-humidity environments

These features go beyond basic power conversion—they integrate seamlessly into the broader industrial control ecosystem and boost system resilience.

Certifications and Compliance Guarantee

Partnering with a high-end manufacturer ensures you receive products that are already compliant with CE, RoHS, UL, and ISO standards. This reduces the compliance burden for your team and avoids delays during equipment audits or third-party inspections. Furthermore, having test reports and certifications readily available helps speed up the deployment phase in export markets or when bidding on government or utility-scale projects.

Responsive Technical and After-Sales Support

Support is more than just a contact form on a website. Reputable manufacturers maintain regional support centers, offer real-time application engineering advice, and respond quickly to technical queries. This level of support is especially important when your system experiences unexpected load behavior, compatibility issues, or requires fine-tuning in a complex installation. It's not just about the product—it's about peace of mind over the product's lifecycle.

Case in Point

A system integrator managing the electrical controls of a logistics automation warehouse opted for SMPS units from a top-rated brand. Over three years of operation, their maintenance logs showed zero SMPS failures across 60+ cabinets. When expanding to a second site, the decision to use the same supplier saved weeks of design and testing time, and ensured seamless compatibility with existing infrastructure.

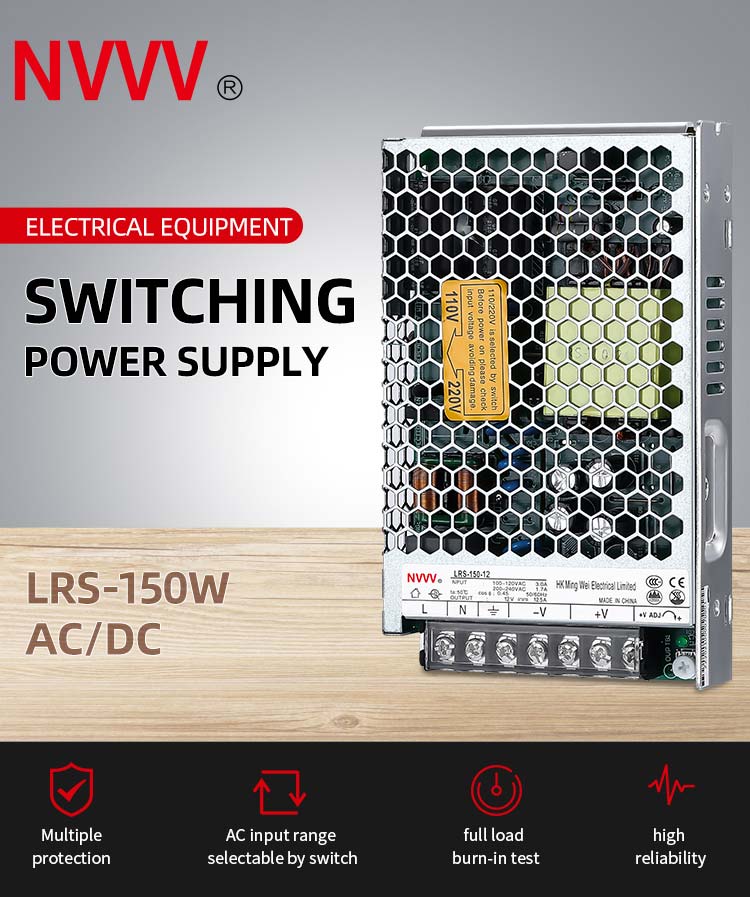

Conclusion: Choosing the Right SMPS Partner

For industrial operations that depend on uninterrupted power, switched mode power supplies are more than just a technical component—they are the backbone of system reliability. Selecting the right supplier ensures efficiency, long-term durability, and regulatory compliance. NVVV provides a wide range of industrial-grade SMPS solutions designed for automation, manufacturing, infrastructure, and energy sectors, backed by strong engineering expertise and global certifications