Switching Mode Power Supply Selection Guide: Avoid These Mistakes With 5 Simple Questions

In industrial automation, smart infrastructure, and communication systems, switching mode power supplies (SMPS) serve as the backbone of stable and efficient power delivery. But with so many choices available, how do you know which one is right for your setup? These five key questions can help you make a smarter investment—technically and financially.

Table of Contents

How Does a Switching Mode Power Supply Actually Work?

What Performance Benefits Can SMPS Offer Over Linear Power Supplies?

Where Are Switching Mode Power Supplies Commonly Used?

Which Technical Specs Should You Pay Close Attention To?

How Do You Choose an SMPS That Will Last in Harsh Conditions?

Conclusion: Maximize Performance by Choosing the Right SMPS

How Does a Switching Mode Power Supply Actually Work?

A switching mode power supply (SMPS) operates using high-frequency electronic switching to convert electrical energy from one form to another—typically from AC (alternating current) to regulated DC (direct current). This method enables far greater efficiency compared to traditional linear power supplies by minimizing energy lost as heat.

Core Operating Principles

Unlike linear supplies, which drop excess voltage through resistive components, SMPS rapidly switches power transistors (like MOSFETs) on and off—usually tens or hundreds of thousands of times per second. These high-speed pulses are then shaped and filtered through magnetic and electronic components to produce a steady output voltage.

The major stages involved include:

Rectification and filtering of AC input into unregulated DC

Switching section, where transistors chop DC into high-frequency signals

Transformer isolation and voltage adjustment using ferrite-core transformers

Output rectification and filtering to deliver smooth DC power

Feedback control, which regulates output to remain within a defined voltage window despite load changes

Efficiency Through High Frequency

Because switching occurs at high frequencies (typically from 20kHz to over 1MHz), the magnetic components like transformers and inductors can be made much smaller and lighter. This is why SMPS units are compact and lightweight while still delivering high power output with minimal losses.

Typical Use Case Example

For instance, in a control cabinet powering multiple programmable logic controllers (PLCs) and sensors, a 24V DC SMPS can regulate voltage precisely even if devices are switched on and off rapidly. Its ability to detect and respond to load changes in milliseconds makes it ideal for such real-time automation environments.

In Summary

The secret to SMPS efficiency lies in switching frequency and feedback control, which allow for precision, energy savings, and smaller size—all critical for modern industrial and commercial systems.

What Performance Benefits Can SMPS Offer Over Linear Power Supplies?

When selecting a power solution for industrial or commercial use, understanding the real-world advantages of a switch mode power supply (SMPS) over traditional linear power supplies is crucial. While both serve the same fundamental purpose—converting and regulating electrical energy—the way they achieve this has a major impact on efficiency, size, and heat management.

Dramatic Improvements in Efficiency

One of the most significant performance gains offered by SMPS is its high conversion efficiency, typically reaching 85% to 95%. In contrast, linear power supplies often lose a large portion of input energy as heat, yielding efficiencies in the range of just 40% to 65%. Over time, this efficiency difference translates to lower energy costs, reduced heat output, and less wear on system components.

For businesses running multiple power supplies simultaneously—such as automation lines or server farms—the cumulative energy savings from SMPS can lead to measurable ROI within months.

Compact Size, Lightweight Design

Because SMPS operates at high frequencies, the transformers and capacitors used can be significantly smaller. This allows for compact designs that are easier to install, especially in tight control cabinets, mobile systems, or panel enclosures. Weight savings also reduce strain on mounting structures, which is particularly important in transport or mobile applications.

Lower Heat = Less Cooling Equipment

Less energy loss as heat means cooler operating temperatures. This reduces or eliminates the need for additional cooling equipment like fans or ventilation systems. Not only does this cut down on noise and maintenance, but it also increases system reliability, particularly in sealed or dust-prone environments.

Faster Dynamic Response

SMPS units also feature superior response to load changes, meaning they can handle rapidly shifting power demands more smoothly than linear supplies. This is especially beneficial in applications with frequent on-off cycles, such as automated machinery, LED displays, or digital communication systems.

Performance Comparison: SMPS vs. Linear Power Supply

|

Feature |

Switching Mode Power Supply (SMPS) |

Linear Power Supply |

|

Efficiency |

85–95% |

40–65% |

|

Size and Weight |

Compact, lightweight |

Bulky, heavy |

|

Heat Generation |

Low |

High |

|

Response Time |

Fast (adaptive) |

Slow (passive) |

|

Cooling Requirements |

Minimal or none |

Often needs active cooling |

|

Initial Cost |

Slightly higher |

Lower |

|

Long-Term Operating Cost |

Lower due to energy savings |

Higher due to inefficiencies |

In short, SMPS offers a more efficient, compact, and responsive power solution—making it the preferred choice in most modern industrial environments.

Where Are Switching Mode Power Supplies Commonly Used?

A switching power supply (SMPS) is a behind-the-scenes powerhouse in countless electrical systems across industries. From compact control boxes to city-wide infrastructure, SMPS units provide the stable, efficient, and space-saving DC power required by modern devices.

Industrial Automation Systems

SMPS is indispensable in industrial settings. It's commonly used to power:

PLCs (Programmable Logic Controllers)

Proximity sensors and encoders

Relay modules

Human-Machine Interfaces (HMIs)

In automated factories and process lines, these components require reliable 24V DC output with minimal voltage fluctuation—even when machines are rapidly switching on and off. SMPS units with fast transient response and overcurrent protection excel in these dynamic conditions.

Smart Building and Security Systems

In commercial buildings and infrastructure, SMPS units are embedded within:

Access control systems

Fire alarm panels

Security cameras and motion sensors

Lighting controllers

Their compact size and energy efficiency make them ideal for ceiling or wall-mounted enclosures. For security-critical environments, low ripple output is essential to avoid interference with signal lines or data transmission.

Telecommunications and Data Centers

In telecom base stations and server racks, SMPS units support:

Signal repeaters

Router and switch backup

Uninterruptible Power Supplies (UPS)

Cooling control circuits

Telecom applications often require 48V DC output, and demand redundancy, hot-swappability, and surge protection—features many high-end SMPS units are built to support.

Medical, Laboratory, and Testing Equipment

High-precision environments such as laboratories and diagnostic labs rely on SMPS for:

Stable and noise-free voltage output

Compact design for portable instruments

Long service life with minimal heat generation

Here, EMI performance becomes critical, since even small voltage irregularities could interfere with readings or device calibration.

Common SMPS Applications and Recommended Types

|

Application Area |

Typical Use Cases |

Recommended SMPS Type |

|

Industrial Automation |

PLCs, sensors, control modules |

DIN rail mount, 24V output |

|

Building Management |

Access control, alarms, LED panels |

Enclosed, compact, fanless design |

|

Telecommunications |

Base stations, routers, signal distribution units |

High-power 48V SMPS with backup |

|

Medical & Laboratory |

Analyzers, imaging devices, data loggers |

Low-noise, EMI-shielded open-frame |

|

Outdoor/Harsh Environments |

Irrigation, lighting control, remote monitoring |

IP-rated, wide-temp range units |

Whether it's on the factory floor or inside a solar-powered IoT device, SMPS plays a vital role in powering modern operations reliably and efficiently.

Which Technical Specs Should You Pay Close Attention To?

Choosing the right switched mode power supply (SMPS) means going beyond voltage and current ratings. To ensure optimal performance, safety, and long-term compatibility, a careful review of several key technical parameters is essential—especially when the power supply will be integrated into mission-critical or harsh environments.

Input Voltage Range

A wide input voltage range provides greater installation flexibility and protects against unstable power grids, which are common in many developing or industrial regions. Many modern SMPS models support 85–264V AC or 100–370V DC, making them compatible with both global grid standards and backup energy systems like solar or generators.

Tip: For fluctuating supply conditions, opt for SMPS units with active input correction and surge tolerance.

Output Voltage and Current Rating

This seems basic, but it's crucial: make sure your SMPS can consistently deliver the required DC output voltage (e.g., 5V, 12V, 24V, 48V) under full load, and preferably a bit beyond for safety margin.

Some high-demand systems may experience spikes or inrush current at startup. SMPS with current limiting and soft start features are ideal in such cases to prevent tripping or shutdown.

Ripple and Noise Suppression

Low output ripple and noise are vital in sensitive applications, such as:

Communication systems

Audio devices

Data acquisition modules

Medical instrumentation

Ideal ripple levels should be below 50mVp-p for standard use, and <20mVp-p for high-precision environments.

High ripple can cause unpredictable behavior or data corruption in digital circuits. Choose models with multi-stage filtering and shielding where needed.

Regulation Tolerance and Hold-Up Time

Line Regulation: Measures how well the SMPS maintains output during input voltage changes.

Load Regulation: Assesses stability under varying output loads.

Hold-Up Time: Refers to how long the output remains stable after input power is lost—key for critical applications.

|

Spec |

Target Value (Industrial Grade) |

|

Line Regulation |

±0.5% or better |

|

Load Regulation |

±1% or better |

|

Ripple & Noise |

≤ 50mVp-p (standard), ≤ 20mVp-p (sensitive use) |

|

Hold-Up Time |

≥ 10ms at full load |

|

Temperature Coefficient |

≤ 0.02%/°C |

Built-In Protections You Shouldn't Ignore

To protect your equipment and the power supply itself, look for these standard safety features:

Overvoltage Protection (OVP): Protects downstream components from voltage spikes.

Overcurrent Protection (OCP): Prevents overheating or failure from load surges.

Short Circuit Protection (SCP): Cuts output during faults to avoid permanent damage.

Overtemperature Shutdown (OTP): Shuts down the unit when internal temperature exceeds safe limits.

Well-protected SMPS units last longer, require less maintenance, and reduce the risk of unplanned downtime.

How Do You Choose an SMPS That Will Last in Harsh Conditions?

Not all environments are climate-controlled or clean. Many industrial, outdoor, and mobile applications subject power supplies to extreme temperatures, dust, moisture, vibration, or unstable electrical input. Choosing an SMPS that can survive and perform under these challenges requires attention to specific design features and quality indicators.

Temperature Tolerance

In regions like the Middle East, ambient temperatures can regularly exceed 50°C, especially inside enclosures exposed to sunlight or heat-generating machinery. On the other hand, certain European installations may experience sub-zero conditions during winter.

Look for SMPS models rated for –25°C to +70°C, or even up to +85°C with derating curves clearly documented.

Also consider thermal protection features—some models incorporate automatic shutdown and restart based on internal temperature, preventing catastrophic failure from overheating.

Enclosure Strength and Ingress Protection

Harsh environments often come with exposure to dust, humidity, water splashes, or even corrosive gases. In these cases, the physical protection of the unit becomes just as important as the electrical specification.

For indoor dusty environments: choose fanless, sealed enclosures.

For outdoor or industrial washdown areas: select IP-rated models (e.g., IP65 or IP67).

For coastal or chemical plants: look for conformal coating to protect the PCB against corrosion.

Tip: Always cross-check whether the SMPS's IP rating matches your operating environment, especially in electrical panels without climate control.

EMI, Vibration, and Mechanical Stress Resistance

In high-speed production environments or mobile machinery, vibration and shock can degrade components over time. A robust SMPS should include:

Secure PCB mounting

Thickened aluminum or steel enclosures

Anti-vibration pads or potting

Also, in facilities packed with digital equipment, EMI emissions can interfere with nearby systems. Look for units that comply with EMC Class A (industrial) or Class B (commercial) and include proper filtering.

✅ MTBF and Reliability Ratings

Reliability isn't just about features—it's about tested lifespan. Check for:

MTBF (Mean Time Between Failures) over 100,000 hours at full load, 25°C

Compliance with CE, RoHS, UL, or CB standards

Evidence of testing under shock, humidity, and temperature cycles

Reputable manufacturers often publish environmental test data in datasheets or whitepapers—don't overlook this documentation.

Partnering With a Trusted Brand

Finally, long-term durability often comes down to manufacturer experience and product consistency. Reliable brands offer:

Documented product traceability

Ongoing firmware or hardware support

Consistent supply and cross-model compatibility

Clear warranty policies

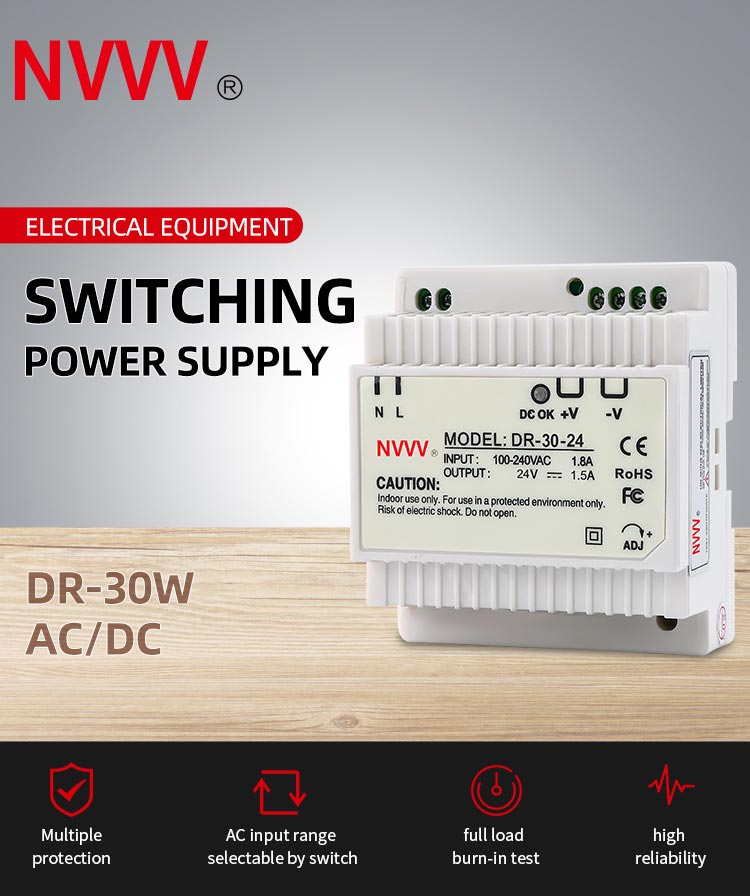

A good example is NVVV, which offers a complete SMPS product line designed for challenging applications. Their units integrate wide input ranges, thermal protection, and IP-rated housings—ideal for harsh or unpredictable working environments.

Conclusion: Maximize Performance by Choosing the Right SMPS

A high-quality switching mode power supply is more than just a component—it's a safeguard for your equipment and a long-term investment in operational efficiency. Whether you're powering a sensitive control circuit in an industrial automation system or maintaining uptime in an outdoor monitoring station, selecting the right SMPS ensures stability, safety, and reliability across all operating conditions.

By asking the right questions—about efficiency, applications, specs, durability, and design—you reduce the risk of power-related failures and gain confidence in your system's performance.

For those looking for industrial-grade, long-lasting, and technically robust SMPS solutions, NVVV offers a full range of products designed to meet the evolving needs of modern infrastructure—combining smart design with durable performance and global compliance.